SICE A13 CCTV

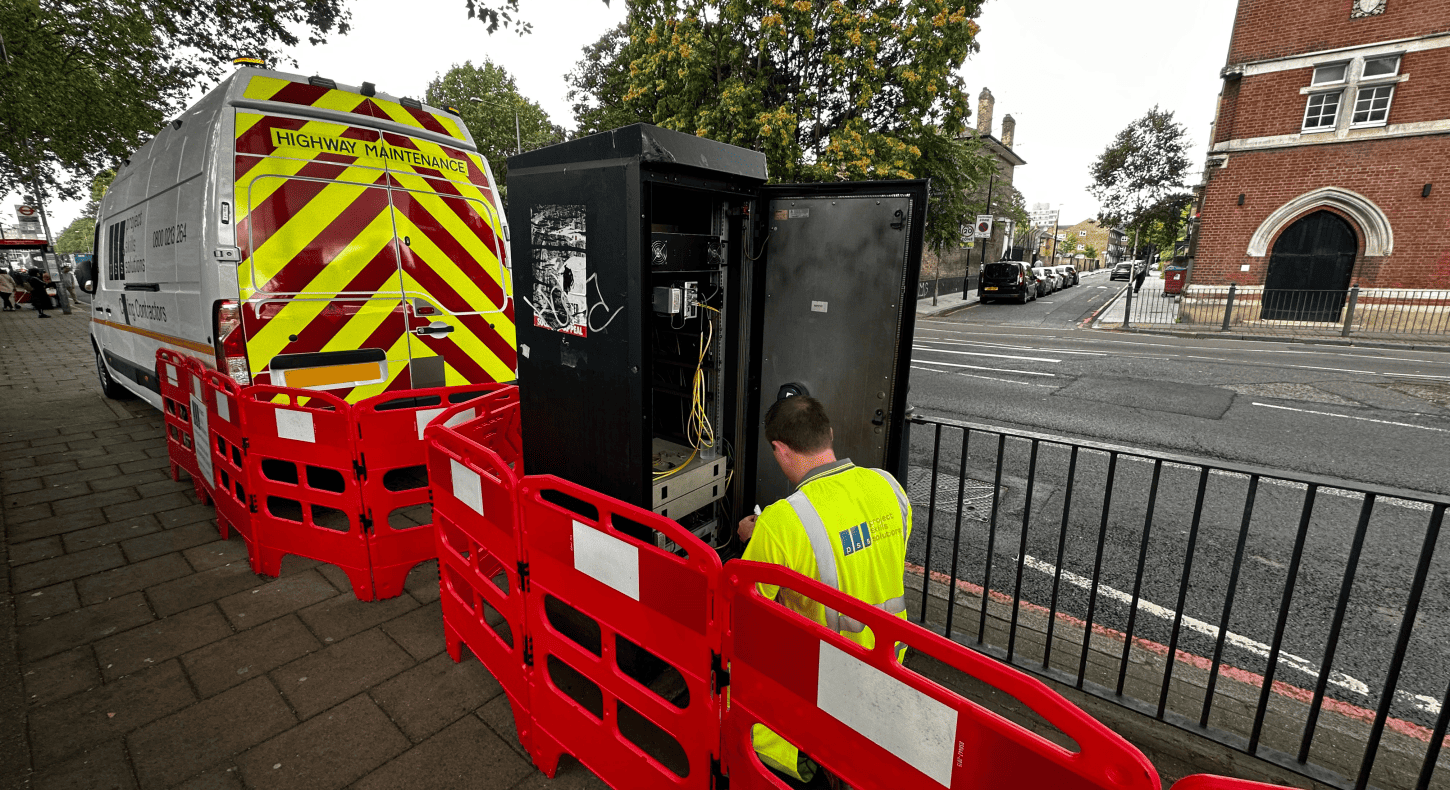

Our client, SICE, use a network of CCTV cameras on the A13 to monitor traffic. They control and maintain the system of 358 cameras that together, allow it to cover a portion of the A13.

The Challenge:

Following a recent CCTV camera upgrade, SICE were experiencing the camera feed dropping out at random times throughout the day. We had a meeting with the client over Teams to discuss the issue. It was agreed that PSS Fibre engineers would attend the section of the network where the issues were occurring and run a test between the joints (MUXs) and the cameras (monitoring points) to discover where a CCTV cable repair may be needed.

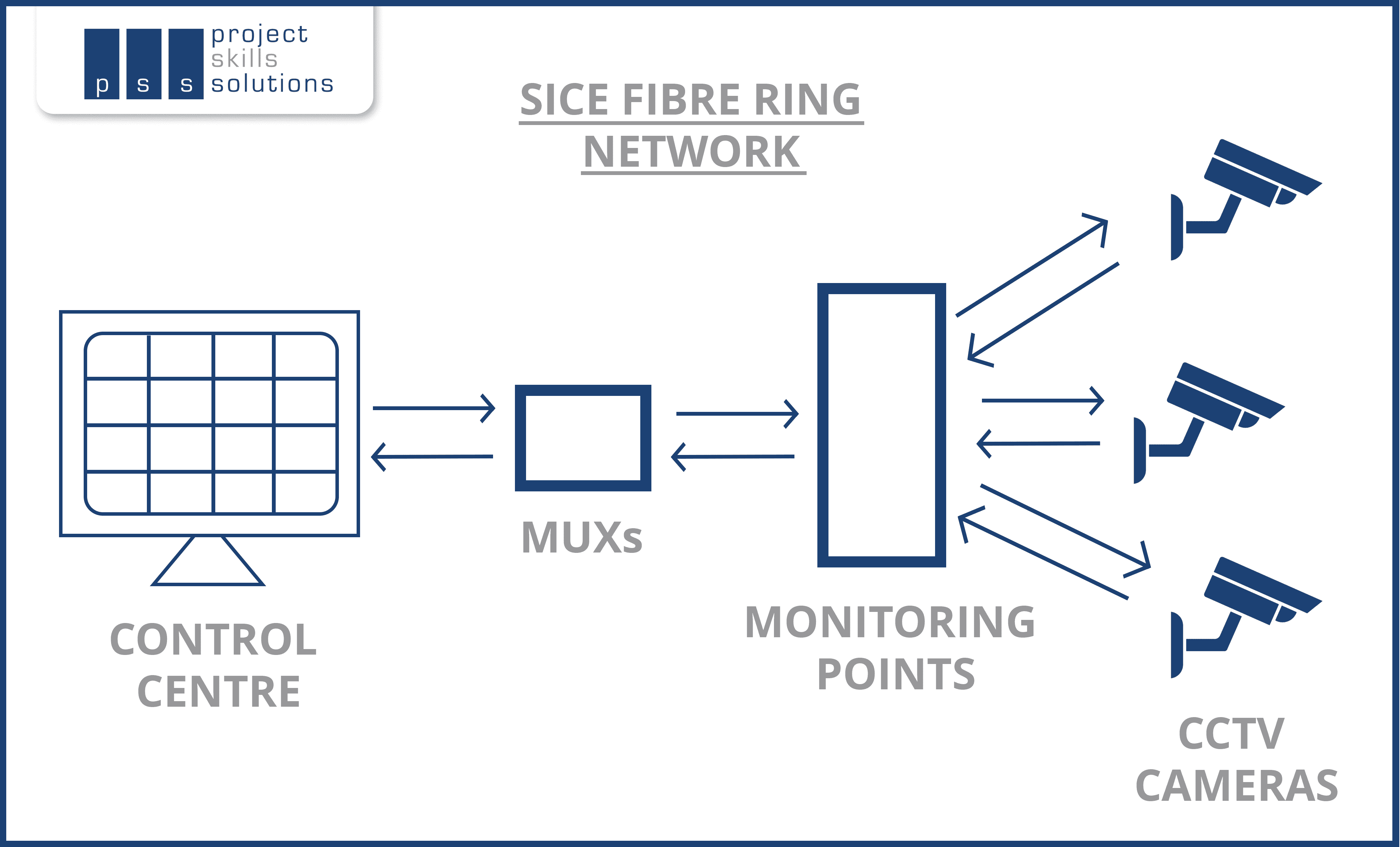

As can be seen from the infographic above, the ‘fibre ring’ design of the A13 CCTV camera network has been cleverly designed:

- Firstly, if a camera cannot be accessed via one direction on the ring, then a connection can be made via an alternative route in the other direction

- Secondly, faults can be more easily located via the many access points of the infrastructure through MUXs and Monitoring points located around the ring

Infrastructure challenges:

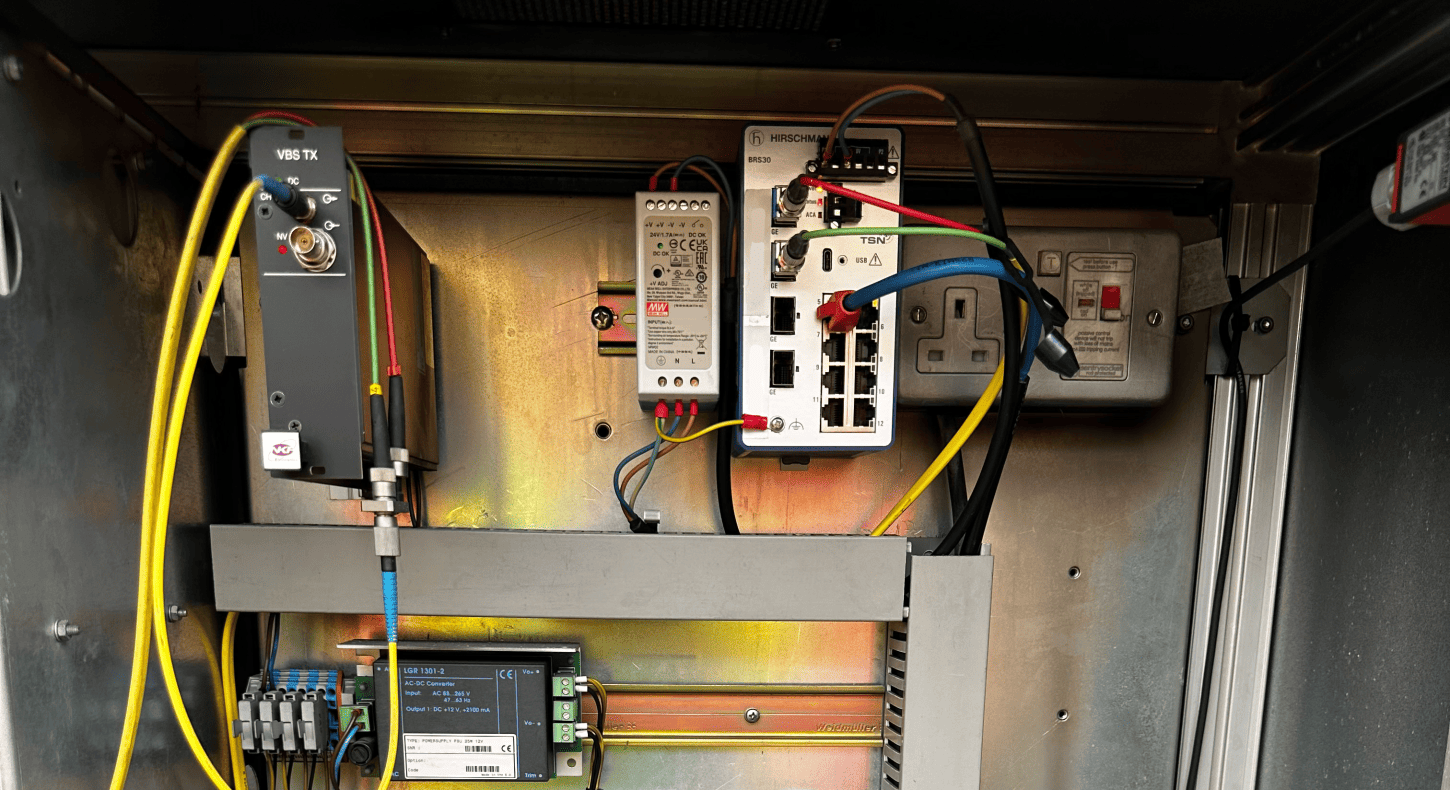

- Fibre was single mode 9/125 16 core

- Connection type was FC/PC

Single mode fibre optic cables are designed to carry a single ray of light. This is ideal for high speed and long distance networks. Having 16 cores means that there are 16 separate fibre strands within the cable. Two fibre strands will be used per monitoring point (which link to any number of cameras from that monitoring point). Therefore, if there are 8 fibre cores in use at the point of installation, there would be 8 spare fibre cores. This allows for any CCTV cable repairs, extra network switches to be added etc. Once all the fibre strands are in use or have been for repairs, the only option is to renew the cable completely.

FC/PC connectors connect and terminate these fibre optic cables. They can be used with lots of different types of fibre, but have a few common issues that are worth checking if faults are found. They are sensitive to contamination. Dirt and any physical contact with the connector can significantly affect the performance of the connections.

The result of the fault testing:

Due to the design, the client was able to re-route the cameras to allow for the identified stretch of faulty fibre to be disconnected and tested, ensuring there was no downtime on the whole system.

- We tested from MUX6 to MUX4 (a run of 2,700m of fibre) which showed a large decibel loss at 2,700m

- We attended to MUX 4 where we tested back to MUX 6. It was found to have a large decibel loss at 0m

How the CCTV cable repair was carried out

- With some investigation, the first large loss was found to be caused by a fibre bulkhead (part of the connector) that had significant contamination. This was replaced and the test carried out again. This time a fault was flagged at 540m from MUX4.

- We located 540m to be at a monitoring point. We used a light source to determine the correct fibre core which had the issue within the fibre splice trays. The fibre core was unfortunately too short to re-splice. Therefore, we identified another core which was unused and tested this to see if it could be used as an alternative. This core still had a fault at 540m, however it was long enough to re-splice the joint. The engineer completed the fusion splice and we tested again from the motoring point to MUX4 and MUX6 to the motoring point. The test came back without faults, indicating that the issue should now have been rectified.

CCTV Cable fault: The Result

- Over 2,700m tested

- Bulkhead replaced

- Joints re-spliced

Happy with the test results, we spoke to the client who re-routed the CCTV cameras back along their original route. The cameras were now all back up and running without camera feed drops.

Interested in hearing what PSS Installations can bring to your project? Contact us today either by phone or using our contact form.

Other case studies you might be interested in: